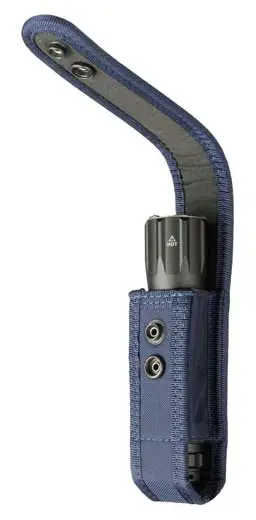

Case Study: Heat Resistant Torch Pouch

The Problem

An Australian police force customer approached us with a frustrating problem - their new, high powered LED torch was being accidentally switched on in in its pouch, melting the lid of the pouch supplied by its manufacturer.

The Solution

We developed a custom designed pouch which addressed the issue in numerous ways:

- the geometry of the gusset and body is designed to reduce the likelihood of torch rotation in the pouch activating the on/off dial,

- the lid inner is lined with heat resistant Nomex - the same material used in firefighting suits,

- the lid has an air gap to help reduce inner temperatures

- the lid has dual, opposing press studs to maintain the lid air gap

Rigorously Engineered

To validate that the solution will be robust, even in the most demanding environments, the pouch design was tested in a lab oven for 45 minutes at up to 60°C, with the torch on full power. Testing was done in the correct/full insertion, plus partial and misaligned insertion.

All surface temperatures were below the melting point of the pouch lid materials and no damage was observed.

The customer also successfully validated that the solution was effective on a pre-production sample.

Because we had a longstanding relationship with this customer, the development work was done at no cost, demonstrating the value of having a local supplier partner with deep technical expertise and local manufacturing capability.

If you are a government department or corporate customer looking for a custom load carriage solution, please contact us to discuss your requirements.